Touchups on Inside or Outside Corners and More

:max_bytes(150000):strip_icc():format(webp)/drywall-taping-troubleshooting-1821476_hero-b7fd7ff0497e4421b2b37d58f1a8117f.jpg)

Drywall finishing—including drywall taping—is by far the most challenging part of drywall installation, and it’s where some do-it-yourselfers run into the most problems. The process requires several different coats of mud that must be dried and smoothed properly, and at first, it can seem more complicated than it actually is.

While the skill of perfect finishing comes only through practice, several common drywall issues are easily corrected with a better technique or materials, or both. Thankfully, there are simple ways for beginners to mud and tape drywall like a pro.

How to Tape and Mud Drywall

The easiest way to mud and tape drywall is to cover the screw holes, apply a layer of mud before taping, smooth the joints, then follow up with another layer of mud after letting it dry overnight. You’ll need two drywall knives approximately sized 6- and 10-or 12-inch, paper drywall tape, pre-mixed drywall mud, and a drywall sanding screen or sandpaper.

- Apply Mud to Screw HolesUse the drywall knife to apply joint compound, or mud, across screw holes in the face of the drywall.

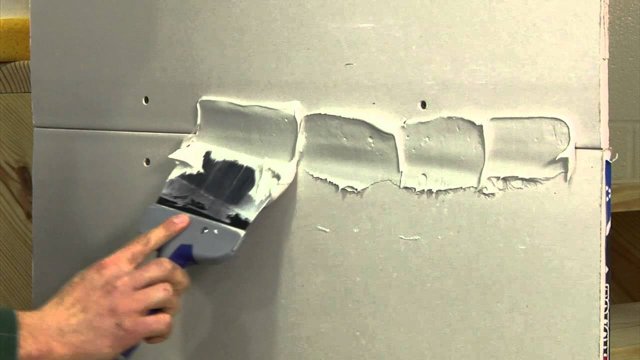

- Apply Mud to JointsWhen using paper tape, mud the drywall joints before taping. Use the 6-inch drywall knife to apply mud to the seams between sheets of drywall. Apply only a thin coat, as this will be used to embed the drywall tape.

- Apply Tape to Mudded JointsBy hand, press the drywall tape into the wet mud. Use the flat of your hand rather than your fingers.

- Smooth Down TapeFurther smooth and embed the tape in the mud base with the 6-inch drywall knife. Wipe away any excess and deposit it back in the drywall bucket or tray. After applying the first layer of mud under the tape, you can add one more thin coat of mud to get a smooth finish.

- Sand Dry MudAfter taping and smoothing drywall, wait one day to allow the mixture to dry overnight. Next, lightly sand off any bumps before applying another coat of mud. Go easy with the sanding at this point to avoid abrading the drywall tape paper.

- Apply Second Coat of MudWith the 10- or 12-inch drywall knife, apply a second coat of mud to the seam. Let dry overnight.

- Apply Third Coat of MudWith the 10- or 12-inch drywall knife, apply a thin layer of mud to the seam. Feather the mud outward to blend the seam with the rest of the board.

- SandSand the drywall one last time.

Drywall Taping and Mudding Troubleshooting

Inside drywall corners look ragged, not straight

Instead of creasing the all-paper tape that you might be used to, try mudding and taping inside drywall corners with metal-reinforced corner tape.

Metal-reinforced tape combines a metal angle with paper flanges for a perfectly shaped and smooth inside corner: The tape does the creasing for you. The metal gives your drywall knife a smooth, rigid surface to ride along when taping the corner. This process can also be used when mudding and taping drywall ceiling corners.

Outside drywall corners are fragile or rough

Instead of using standard paper options to mud and tape outside corners, use metal or plastic outside corner beads.

The best practice is to use corner bead because it is more durable and easier to install than paper-only corners. Save the paper tape for outside corners that never receive any traffic, such as bulkheads or skylight shafts. Any outside corner within reach should use a rigid bead.

Drywall mud dries before putting on the tape

It’s common to apply the drywall mud to the wall, then find that the paper tape isn’t sticking well because the mud has dried.

Before you apply the joint compound or mud, cut your paper drywall tape to length and pre-crease it. You’ll save yourself a crucial few seconds.

If you’re using metal-reinforced tape, cut it to length and have it at the ready before mudding the corner. In either case, it’s also easier to measure for your tape length before there’s mud on the wall.

Drywall tape shows through the mud

If you keep seeing the drywall tape under the mud, your coating is too thin.

Use three layers: tape coat, filler coat, and final coat. The tape actually should show through the filler coat. If it doesn’t, your filler coat is too thick. Covering the tape comes only with the final coat or coats. If your initial final coat doesn’t cover the tape, apply more coats, but keep them thin.

Mesh tape shows through the butt joints

This can be hard to fix, and it’s why a lot of drywall workers prefer paper tape on butt joints. If you’ve already mudded over mesh tape and it’s still showing, keep applying thin final coats with a 10- or 12-inch drywall knife. Gradually build up the joint in the middle—to cover the tape—and feather it at both sides to make it all look flat. Mesh tape is also commonly used for mudding and taping drywall patches, so it’s important to use the same smoothing process for these projects.

Butt Joint

Butt joints are seams where two panels meet at their square (not tapered) edges, so there’s no recess for the tape and mud.

Paper tape is visible on butt joints

Butt joints are difficult to cover, even with paper tape. Since you have no edge tapers creating a recess, the tape and mud are riding on top of the drywall.

Carefully apply the final coat or coats and feather it out well with the 10- or 12-inch knife. One error with butt joints is to use too much mud under the tape, creating a hump that is hard to hide with all of the thin final coats.

Applying some pressure to the knife when smoothing the tape over the initial layer of mud helps to squeeze out excess mud from behind the tape. Ideally, though, don’t put too much mud there to begin with.

Drywall seams are cracking

Drywall joints crack for many different reasons. Over the door and window openings, joints can crack due to movement in the wall framing. The movement is unavoidable, so the best solution is to make the taped joints as strong as possible. Mesh drywall tape is easier when it comes to drywall for beginners, but it is more likely to crack over time.

The paper tape itself is less strong than mesh tape, and paper is also less elastic and doesn’t stretch as mesh tape does. This is why some drywallers prefer paper for these high-stress joints.

If you do decide to mud and tape with mesh in these areas, always use a setting-type mud for the first coat over the tape. Setting mud is stronger than pre-mixed all-purpose mud and helps compensate for the elasticity of mesh tape.

Any drywall joint can also crack if the mud is applied too thick or too quickly. To prevent cracking, don’t use more mud than you need for any of the coats, and let each coat dry completely before adding the next.

Tip

To cut down on dust, use a wet sponge between coats instead of dry-sanding with sandpaper or a drywall sanding screen.